| Sign In | Join Free | My webtextiles.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My webtextiles.com |

|

Brand Name : LIANDA

Certification : CE,ISO9001

Place of Origin : China

MOQ : 1set

Payment Terms : T/T, L/C

Supply Ability : 100 sets/year

Delivery Time : 5~8weeks

Voltage : Customized

Warranty : 12 months

Capacity : 100-1000KG/H

Applied : APET, GPET, CPET, PLA, HIPS, PE, ABS, EVA ,PC, PEEK, PPS, PTFE, PEEK, TPU, TPE e.g

Service : 24 hours

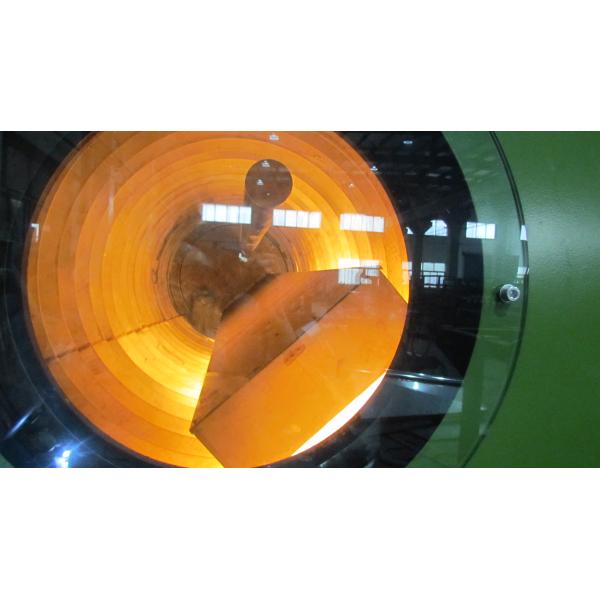

PET Sheet extrusion Dry and Crystallization, PLA PET PBAT Dehumidifier, crystal dryer

Advantage of IRD Processing

| 1 | Rotary drum design | To dry the material evenly |

| The spiral coils design of the drum ensure the good mixture of the raw material to avoid material clumping | ||

| 2 | Retention time | Depends on the speed of Rotary drum |

| The speed can be adjustable by the property of drying material | ||

| 3 | PLC Controlling system | The material retention time,drum rotating speed |

| The Infrared lamps performance, drying temperature | ||

| The feeding speed of Vacuum feeder | ||

| 4 | Reproducibility | Recipes and process parameters can be stored in the controlling system to ensure opimal and reproducible results |

| 5 | In one step | Drying and crystallization in one step |

| 6 | High efficiency | Minutes drying and crystallization instead of hours( Compared to conventional dehumidifier and crystallizer) |

| 7 | Fast cleaning | Allow for easy and fast cleaning. Rapid product change-over |

Machine photos

|

|

PET Sheet extrusion Dry and Crystallization, PLA PET PBAT Dehumidifier, crystal dryer Images |